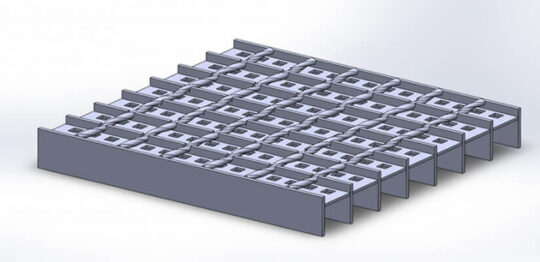

Perforated Sheet Grating

Perforated sheet metal, are flat metal plates produced by drilling holes on metal sheet plates. Perforated sheet models, also defined as perforated metal or perforated sheet metal, are produced flexibly with the desired sheet thickness, hole size, shape and distance between holes. Perforated sheet metal models are produced exclusively by the System Platform Grating Metal team according to your project and needs and delivered to you just in time.

Perforated sheet models are frequently preferred for filtration processes as well as ventilation products due to light, water and air permeability. The holes to be drilled on perforated metal products are determined completely specific to your project and produced in different sizes. Functional and attractive results are produced with perforated sheet metal models that offer unique solutions for projects with high aesthetic concerns.

After hot rolling is applied on perforated sheet models, the desired holes are shaped by cold rolling process. Since the holes drilled on perforated metals increase strength, perforated sheets stand out for being resistant to impacts.

Perforated sheet models are produced in different types such as steel, stainless steel, aluminum, copper, titanium, zinc by the system platform grid metal team specializing in the field.

Perforated Sheet Advantages

As Sistem Platform Metal Grating, we work diligently for each project and produce strong and functional perforated sheet metal products for your needs. We produce professional solutions with designs for your needs with square, hexagonal or octagonal hole sheet products together with flat or round opening holes.

- Since it is produced from a single plate, it is shock resistant and long-lasting.

- Since the shape, size and thickness of the holes drilled on the metal plates can be customized according to your project, it offers flexible solution.

- Holes on perforated metals are highly preferred in industrial projects due to light, water and air permeability.

- It allows you to make professional touches to your projects with its powerful and different designs.

- It is functional because it is permeable like air, water, light. For this reason, perforated sheet metal models can also be used as filters.

- System Platform perforated sheet models stand out with their high quality and economical prices.

How to Choose Perforated Sheet Models?

When choosing perforated sheet metal models, first of all, the expertise, reliability and product quality of the company you will work for should be looked at. Considering the projects that the company you will work with has already carried out and delivered, you can choose the right partner for your project by gaining an idea about the variety of perforated sheet metal products. You can find more detailed information about System Platform perforated sheet metal models here.

In addition to all this, you can search for prices and models for perforated sheet metal models, each of which is designed according to the usage area. By researching the price performance balance according to the model, brand and specifications you will use for your project, you can choose the model that best suits your budget from among the system platform perforated sheet models. You can use perforated sheet metal models for a long time by choosing brands and models that are highly resistant to environmental factors.

You can contact us at any time to get more detailed information about perforated sheet metal models, types and application areas.

Types of Perforated Sheet Raw Materials

Perforated sheet products are produced using steel, stainless steel, aluminum, copper, titanium, zinc (and many other metals) and delivered just in time with high quality and reasonable price.

Types of Perforated Sheet Metal Coating

Types of perforated sheet metal coating are carried out by System Platform in hot dip galvanized, electro galvanized, electrostatic paint, anodized.