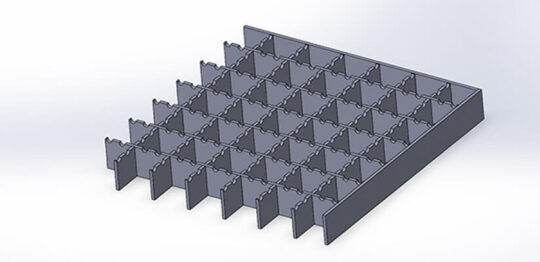

Full Pass Notched Grating

Full Pass Notched Grating models are produced by inverse interlocking of two laces equal to each other with the dimensions of the carrier and binding blades. Through the processing of metal sheet with a press, the grids are added to the non-slip property. Full Pass Notched Grating models offer an advantage due to the fact that its carrying capacity is higher than other grating models and can be used in both aspects. However, it is also quite easy to assemble.

Due to its anti-slip feature, it is also preferred for general use with medium and heavy loads.

Full Pass Notched Grating type products are often used in areas and environments where shifter matter is dense. System Platform Full Pass Notch Grating products are manufactured in high quality, hot-dipped galvanized, painted or uncoated according to your project’s requirements.

Advantages Of Full Pass Notched Grating

Full Pass Notched Grating models, carrier and binder blades are achieved by reverse interlocking two metal sheets equal to each other. Full Pass Notched Grating products can be customized according to the area to be used and the technical specifications of the project to be applied.

- Full Pass Notched Grating models that can be customized to suit your project and needs are often preferred because they are easy to assemble.

- The safety is maximized thanks to the anti-slip property, which is added to the gratings through the processing of the metal sheets with the press in Full Pass Notched Grating.

- System Platform Full Pass Notched Grating models are manufactured with high quality standards and tailored to your request.

You can find detailed information about expanded metal at https://sistemplatform.com.tr/genisletilmis-metal/